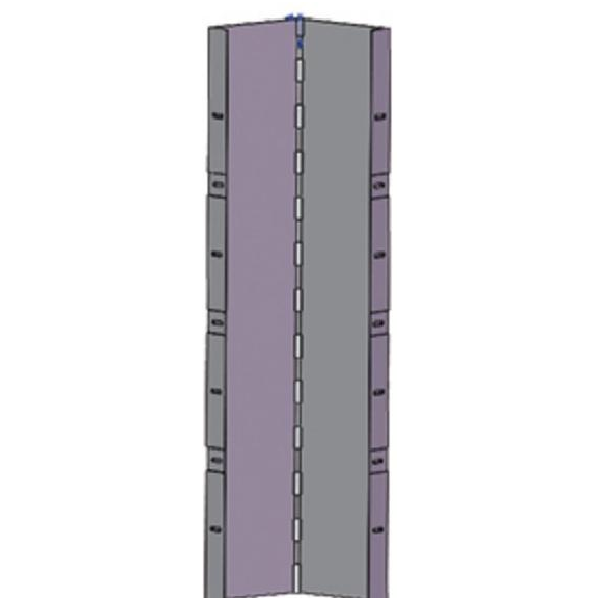

- Description

- Advantage

- Application

- Accessories

1) It is lightweight and mostly crane-independent.

2) It can have welded-in nuts for easy and quick assembly of brackets, guarding rails and other accessories

3) It has less concrete adhesion compared to formwork systems made from different materials

4) It can have powder coating to create an impact- and scratch-resistant surface and ensure easy cleaning

5) It is less expensive to use, especially when constructing a significant number of identical concrete structures

6) It can be used to build the various components of a concrete building, such as walls, slabs, columns, floors and beams

7) It has an outstanding stiffness-to-weight ratio that allows it to withstand high pressures when fresh concrete is poured

1) Easy to handle

It is manufactured with aluminum alloy and every extrusion is specifically designed for high strength and light weight. Even for the biggest panel, it can be easily handled by a single worker.

2) One –time Pouring

It allows for monolithic pouring of all walls, slabs and staircases to suit any housing projects.

3) High Concrete Pouring Rate

-Early Stripping Theory is perfectly integrated with our Aluminum Forwork System. With one-floor forms and three-floor props, the workers will be able to complete the concrete pouring job of one floor in only 4 days.

4) More Reuses

-Typical number of reuses is likely to be≥300 times subject to the correct site practice.

5) Great Recyclable Value

-The used aluminum material is of great recyclable value, over 35% higher than steel.

Related Products

-

SMPRE Form Clamp

Construction Concrete Formwork Clamp is made by High Strength...

SMPRE Form Clamp

Construction Concrete Formwork Clamp is made by High Strength...

-

SMPRE Round Head Pin

Formwork Round Head Pin is used for Aluminum Formwork System. ...

SMPRE Round Head Pin

Formwork Round Head Pin is used for Aluminum Formwork System. ...

-

SMPRE Tie Rods

Tie Rod for Construction Formwork can control the thickness of the...

SMPRE Tie Rods

Tie Rod for Construction Formwork can control the thickness of the...

SMPRE™

SMPRE™

799384842

799384842 +86-17606489157

+86-17606489157 info@simenprecast.com

info@simenprecast.com Simen

Simen